3PC Ball Valve full-bore AISI316/CF8M PTFE seats and seals DN15-100 (G1/2" - G4") PN40 standard butt weld end ABRA-BV61 with ISO mounting top pad flangeDesign decisions, long production experience and strict quality control provide ball valves ABRA-BV the best possible standard tightness - leakage rate corresponding to Rate A according ISO 5208 and GOST54808 and GOST 9544

| Materials specification: description |

|

|

Price-list and available stock rest

ABRA-BV-61 thread ends SS316 stainless steel ball valve:

|

Main technical data:

- Pressure rating - nominal pressure РN40 according to ISO 7268 = WOG1000 (Attention! Abbreviation WOG 1000 means hydraulic test with cold water at 64 bar, but not means PN 64, as sometimes many producers declare. Thats why if you have already bought any ball valve with body marking "WOG1000", please know, that it's pressure nominal is PN40)

- Maximum steam working pressure 8 bar

- Maximum working temperature 180 °C

- Maximum short time temperature 200 °С

- Hydraulic test in cold water 64 bar

Main fields of application - the valve is used as shut-off (on-off) in the following applications:

- Any systems with the following working medias:

- water including seawater, technical, potable, drinking, district heating water, distilled, purified e.t.c.

- salt brines, salt liquors, saline solutions; salt solutions

- water steam (up to 8 bar),

- air, compressed air and neutral gases,

- natural gas, Freons, cooling agents - gaseous

- alcohols, acetic acid (vinegar, ethanoic acid, spirit of verdigris, acetous acid), pure, mixes and solutions

- antifreezes including water glycol mixtures,

- ammonia (hydrogen nitride),

- moderate aggressive acids

- all bases and alkali liquors

- light and heavy petroleum products

- other medias corresponding to material properties

- cold water supply

- hot water supply

- district heating with any standard heat carrier (including antifreezes and non-freezing solutions)

- steam lines up to 200°C,

- condensate loops and lines,

- technical water supply,

- neutral and noble gas pipelines including natural gas,

- water treatment and water intake,

- mineral and synthetic oils transportation e.t.c.

|

|

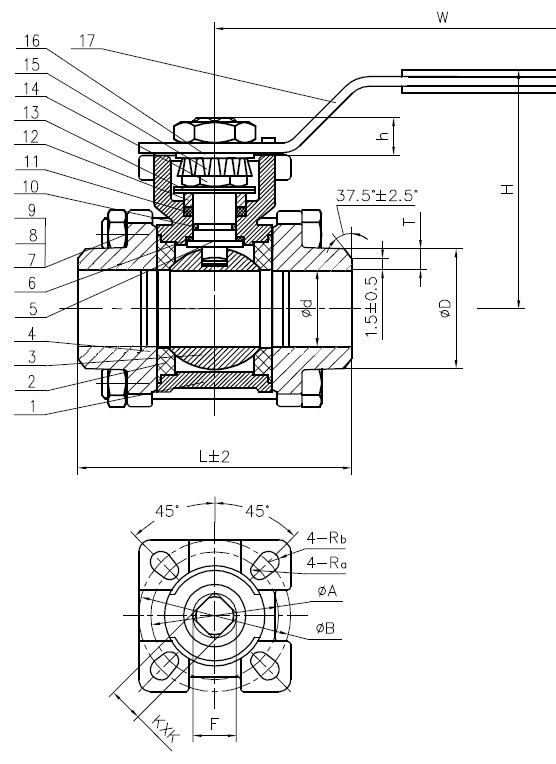

Outline drawing of ball valve ABRA-BV-61 with ISO mounting top pad flange (sizing is in the table below):

|

Ball valve symbols for piping and instrumentation diagram (P&ID):

|

Dimentions, technical characteristics, weight, Kv and Cv - ball valve ABRA-BV-61 butt weld end with ISO mounting top pad flange. Dimentions in mm. Table

DN |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

| 1/2" |

3/4" |

1" |

1 1/4" |

1 1/2" |

2" |

2 1/2" |

3" |

4" |

| PN |

40 |

| Temperature range: |

Maximum short time temperature 200 °C,

Minimal ambient temperature - 60 °C |

| Code |

ABRA-BV61-015 |

ABRA-BV61-020 |

ABRA-BV61-025 |

ABRA-BV61-032 |

ABRA-BV61-040 |

ABRA-BV61-050 |

ABRA-BV61-065 |

ABRA-BV61-080 |

ABRA-BV61-100 |

| ød, mm |

15 |

20 |

25 |

32 |

38 |

50 |

65 |

80 |

100 |

| L - installation length, mm |

65 |

78 |

88 |

102 |

112 |

130 |

180 |

200 |

254 |

| Н - installation height (from pipe axis), mm |

70 |

80 |

85 |

100 |

120 |

140 |

157 |

170 |

185 |

| h, mm |

10 |

10 |

10 |

11 |

15 |

15 |

18 |

19 |

22 |

| Т, mm - ends thickness |

3.0 |

3.0 |

3.5 |

3.7 |

4.0 |

4.0 |

4.5 |

5.0 |

6.0 |

| W - handle, mm |

105 |

120 |

150 |

160 |

180 |

180 |

245 |

245 |

280 |

| KxK, mm, squire |

9x9 |

9x9 |

9x9 |

11x11 |

14x14 |

14x14 |

17x17 |

17x17 |

17x17 |

| М12х1,5 |

М14х1,5 |

М18х1,5 |

М22х1,5 |

| Кv, m3/h (Cv=1,17 Kv) |

18,9 |

47,1 |

66 |

87,6 |

150,8 |

207,4 |

584,4 |

678,6 |

1545,0 |

| Weight, kg |

0,548 |

0,755 |

1,005 |

1,872 |

2,015 |

3,100 |

5,300 |

7,900 |

14,8 |

| F, mm |

12 |

12 |

12 |

14 |

18 |

18 |

22 |

22 |

22 |

| ISO5211/5210 |

F03/F04 |

F03/F04 |

F04/F05 |

F04/F05 |

F05/F07 |

F05/F07 |

F07/F10 |

F07/F10 |

F07/F10 |

| ISO PCD min A / sizing Ra / number of holes |

36/M5x4 |

36/M5x4 |

42/M5x4 |

42/M5x4 |

50/M6x4 |

50/M6x4 |

70/M8x4 |

70/M8x4 |

70/M8x4 |

| ISO PCD max B / sizing Rb / number of holes |

42/M5x4 |

42/M5x4 |

50/M6x4 |

50/M6x4 |

70/M8x4 |

70/M8x4 |

102/M10x4 |

102/M10x4 |

102/M10x4 |

| Torque, N*m, full differential pressure drop* |

7 |

7 |

11 |

17,6 |

38,5 |

55 |

66 |

71,5 |

176 |

*After some rest period the starting torque can be 1,5 - 2 higher then pointed in the table |

Construction - ball valve ABRA-BV-61 butt weld end with ISO mounting top pad flange:

| N |

Description |

QNT |

Material |

| 1 |

Body |

1 |

Stainless steel Grade CF8M = AISI/SAE 316 = W.-nr.1,4401 = DINX5CrNiMo17-12-2 = BS316S16 =EN 58J = AFNOR Z6CND17.11 = UNI X5CrNiMo1712 = UNE F.3543 = SS2347 = GB 0Cr17Ni11Mo2= JIS SUS 316 = GOST03Х17Н14М2 |

| 2 |

Seat |

2 |

PTFE |

| 3 |

Ball |

1 |

Stainless steel AISI/SAE SS 316. Grade CF8M |

| 4 |

Butt weld end |

2 |

Stainless steel AISI/SAE SS 316. Grade CF8M |

| 5 |

Stem |

1 |

Stainless steel AISI/SAE SS 316. Grade CF8M |

| 6 |

Stem gasket |

1 |

PTFE |

| 7 |

Spring washer |

4 |

Stainless steel AISI/SAE SS 304 = Grade CF8 = JIS SUS304 = W.-nr.1.4350 = DIN X5CrNi189 = BS 304S11 = EN 58E = AFNOR Z6CN18.09 = UNI X5CrNi1810 = UNE F.3551 = UNE F.3541 = UNE F.3504 = SS 2332 = GB OCr18Ni9 |

| 8 |

Nut |

4 |

Stainless steel AISI/SAE SS 304 = Grade CF8 |

| 9 |

Bolt |

4 |

Stainless steel AISI/SAE SS 304 = Grade CF8 |

| 10 |

O-ring |

1 |

FPM |

| 11 |

Packing |

1 |

PTFE |

| 12 |

Packing nut |

1 |

Stainless steel AISI/SAE SS 304 = Grade CF8 |

| 13 |

Spring washer |

2 |

Stainless steel AISI/SAE SS 304 = Grade CF8 |

| 14 |

Nut |

2 |

Stainless steel AISI/SAE SS 304 = Grade CF8 |

| 15 |

Crown Washer |

1 |

Stainless steel AISI/SAE SS 304 = Grade CF8 |

| 16 |

Washer |

1 |

Stainless steel AISI/SAE SS 304 = Grade CF8 |

| 17 |

Handle |

1 |

Stainless steel AISI/SAE + PVC |

|

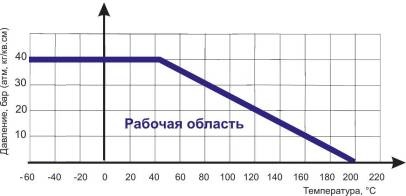

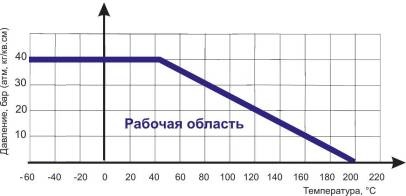

Pressure / Temperature diagram for ball valve ABRA-BV-61 butt weld end with ISO mounting top pad flange:

Diagram defines working pressure/tempetarure range for 3PC ball valve ABRA-BV-61 butt weld end with ISO mounting top pad flange |

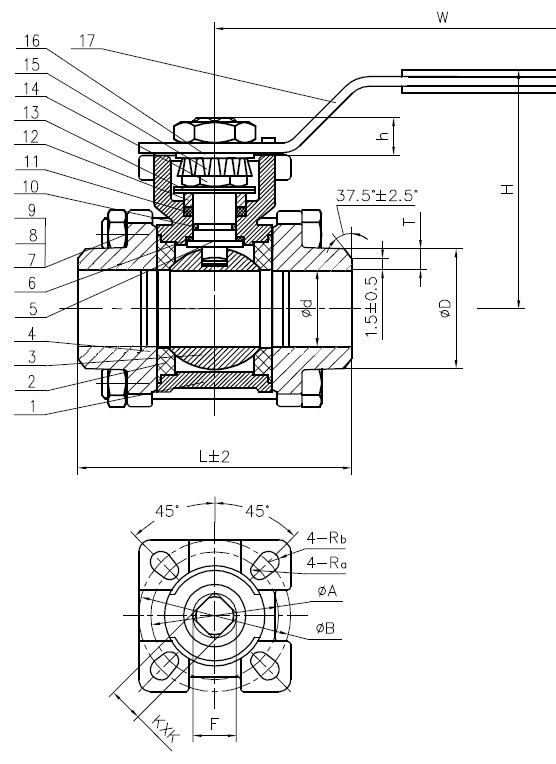

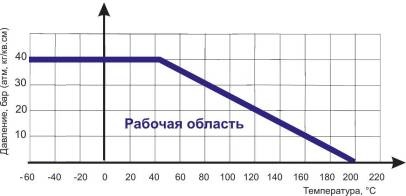

Pressure / Temperature diagram for ball valve ABRA-BV-61A butt weld ends:

Diagram defines working pressure/tempetarure range for 3PC ball valve ABRA-BV-61A |

Installation and maintenance instruction for 3PC ball valve ABRA-BV61A standard Butt Weld End:

- General.

- The valve should be installed only by person who has enough experience, carefully read the following instruction and got appropriate safety training for that kind of work.

- Before mounting you should check the valve for transportation or storage damage. If you find that you should stop mounting until you get Seller's approval.

- Special note for installation of valves with electrical actuators.

- Before installation the valve and the actuator should be set-up properly for for combined operation as it demanded according to actuator producer's manual:

- Check the assembly or assemble valve and actuator;

- While mounted in any orientation but for strictly vertical the actuator should have own supporting structure undependable from the valve;

- Installation of actuator below the valve is strongly not recommended;

- Set up end position limit switches of the actuator for "On" and "Off" and check safety torque limit switches of the actuator;

- Make few cycles of opening and closing of the valve with manual gear of actuator;

- If manual operation ; was well, then you should make proper connection to electricity and make few cycles of opening and closing of the valve automatically. Only after that if operation is normal you can mount the valve to the pipeline.

- Mounting.

- You should obligatory follow "General Installation and Commissioning demands"

- Delete plastic plugs before mounting.

- Before mounting consider hazardous liquids or gases in the pipeline i.e. - what is in the pipeline or what may have been in the pipeline at some previous time. Consider: flammable materials, substances hazardous to health, extremes of temperature.

- Before mounting consider hazardous environment around the product i.e. - Consider: explosion risk areas, lack of oxygen (e.g. tanks, pits), dangerous gases, extremes of temperature, hot surfaces, fire hazard (e.g. during welding), excessive noise, moving machinery. Consider the effect on the complete system of the work proposed. Will any proposed action (e.g. closing isolation valves, electrical isolation) put any other part of the system or any personnel at risk? Dangers might include isolation of vents or protective devices or the rendering ineffective of controls or alarms. Ensure isolation valves are turned on and off in a gradual way to avoid system shocks. Ensure that any pressure is isolated and safely vented to atmospheric pressure. Consider double isolation (double block and bleed) and the locking or labelling of closed valves. Do not assume that the system has depressurized even when the pressure gauge indicates zero. Allow time for temperature to normalize after isolation to avoid the danger of burns and consider whether protective clothing (including safety glasses) is required.

- Before starting work ensure that you have suitable tools and/or consumables available. Use only genuine ABRA replacement parts. Consider whether you and/or others in the vicinity require any protective clothing to protect against the hazards of, for example, chemicals, high/low temperature, radiation, noise, falling objects, and dangers to eyes and face.

- Ball valve can be installed to the pipe in any orientation.

- Ball valve BV61 should be obligatory disassembled before welding ends to the pipeline, and further assembled back to avoid seals and seats damage.

- Ball valves could be installed in any space direction on the pipeline.

-

Bolts tightening torque for 3PC ball valves:

| DN |

8 |

10 |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

| 1/4" |

3/8" |

1/2" |

3/4" |

1" |

1 1/4" |

1 1/2" |

2" |

2 1/2" |

3" |

4" |

| Bolts torque |

Nm |

20 |

20 |

30 |

30 |

30 |

45 |

45 |

55 |

55 |

70 |

70 |

- Maintenance.

- The ball valve should be checked visually not less than once per year or more times if that is necessary according to ambient conditions or/and frequency of operations.

- To avoid trim jam the valve should be run the cycle "fully open"/"fully closed" not less than once every 6 month.

- No special treatment is needed for all lifetime of the valve.

- Transportation and Storage.

- Storage and transportation should be without shocks at temperature range: -60…+65°С.

- No parts or objects are allowed to be placed into ball valve ABRA-BV61.

- The valve should be kept in clean and weatherproof placements.

- During transportation ball valve ABRA-BV61 should be properly protected from damage.

- Attention!

- Don't touch valve in operation due to the possible dangerous temperature.

- Before service or/and mounting works you must ensure that the valve is not under the pressure and don't have dangerous temperature.

- Never delete marking from the valve.

- Guarantee.

- Guarantee is 12 month from installation but not more than 18 month from shipment if all demands of this manual are fulfilled.

- Customers and stockists are reminded that under EC Health, Safety and Environment Law, when returning products to ABRA they must provide information on any hazards and the precautions to be taken due to contamination residues or mechanical damage which may present a health, safety or environmental risk. This information must be provided in writing including Health and Safety data sheets relating to any substances identified as hazardous or potentially hazardous.

|

|